Exhaust flange tool. There are plenty of these available from Ducati bevel twin parts sources on the web. All fit better than the original factory tool. A replacement flange nut costs almost the same. No need to be king kong tight either, head threads are expensive to repair.

Removing

the plug below the left front engine mount requires a 30mm socket (

preferably a thin wall flank drive ), or a special tool if the engine

and header pipes are in place. The tool I fabricated works with the

dipstick in place ( I can be lazy sometimes ). The necessity for the

removal of the plug in situ is uncommon, an oil weep at the washer

being the usual culprit.

Removing

the plug below the left front engine mount requires a 30mm socket (

preferably a thin wall flank drive ), or a special tool if the engine

and header pipes are in place. The tool I fabricated works with the

dipstick in place ( I can be lazy sometimes ). The necessity for the

removal of the plug in situ is uncommon, an oil weep at the washer

being the usual culprit. Bevel

extractor tool is a necessity, there is no acceptable

alternate method for removing the lower bevel bearing holders from the

crankcase. See this image

- 1.Starting thread damaged, therefore extractor will not work.

2. Outer sleeve crushed preventing alignment and position of

new

bearing. A hard to find part totaled !

Bevel

extractor tool is a necessity, there is no acceptable

alternate method for removing the lower bevel bearing holders from the

crankcase. See this image

- 1.Starting thread damaged, therefore extractor will not work.

2. Outer sleeve crushed preventing alignment and position of

new

bearing. A hard to find part totaled ! Holds

the original alternator rotor whilst performing a number of assembly

and disassembly operations, including the right side crank nut. Made of

alloy with crap engraving by owner. Available from a number of

web

shops.

Holds

the original alternator rotor whilst performing a number of assembly

and disassembly operations, including the right side crank nut. Made of

alloy with crap engraving by owner. Available from a number of

web

shops. Clutch

cover removal tool. Yes, the Haynes manual says you can remove

the cover with a claw hammer wedged inside the clutch inspection plate

- choice. Did they think about how it might affect the bearing which

acts as an outrigger for the crankshaft ? There should also be a small

button ( or an 8mm bolt in a pinch ) placed on the

end

of the tool to prevent damage to the end of the crank

when turning.

Clutch

cover removal tool. Yes, the Haynes manual says you can remove

the cover with a claw hammer wedged inside the clutch inspection plate

- choice. Did they think about how it might affect the bearing which

acts as an outrigger for the crankshaft ? There should also be a small

button ( or an 8mm bolt in a pinch ) placed on the

end

of the tool to prevent damage to the end of the crank

when turning. Having

fitted a rare earth magnet to the oil gallery plug on the right

crankcase to catch the furry bits, once a year it requires removal. Its

use allows access to the plug without removing the RH engine pipe. Yes,

it was a 21mm thin wall flank drive socket. Once loosened the plug can

be removed for inspection of the oil gallery and the VeeTwo or RYE

oring oil sieve modification. ( highly recommended )

Having

fitted a rare earth magnet to the oil gallery plug on the right

crankcase to catch the furry bits, once a year it requires removal. Its

use allows access to the plug without removing the RH engine pipe. Yes,

it was a 21mm thin wall flank drive socket. Once loosened the plug can

be removed for inspection of the oil gallery and the VeeTwo or RYE

oring oil sieve modification. ( highly recommended ) Distributor

shaft SKF nut tool. The factory tool is a tad soft, the genuine SKF

tool ( way expensive ) is the best. The tool pictured is a hardened

steel, precisely machined. There's no way out of this one when you need

to remove the distributor shaft to replace a bearing. The SKF nut needs

to be quite tight to act as preload for the the centre bevel trigear

and distributor crank gear mesh.

Distributor

shaft SKF nut tool. The factory tool is a tad soft, the genuine SKF

tool ( way expensive ) is the best. The tool pictured is a hardened

steel, precisely machined. There's no way out of this one when you need

to remove the distributor shaft to replace a bearing. The SKF nut needs

to be quite tight to act as preload for the the centre bevel trigear

and distributor crank gear mesh. These

are a couple of specials. To the left is for the insertion of the crank

main bearings, to the right for the insertion of the main bearing

sleeves. Made as a precaution to ensure precise fit of the components.

Not much time to work when you have warm crankcases and/or cold

sleeves. I recommend VeeTwo sleeves as they come in different sizes or

custom sized when ordering to ensure the correct fit.

These

are a couple of specials. To the left is for the insertion of the crank

main bearings, to the right for the insertion of the main bearing

sleeves. Made as a precaution to ensure precise fit of the components.

Not much time to work when you have warm crankcases and/or cold

sleeves. I recommend VeeTwo sleeves as they come in different sizes or

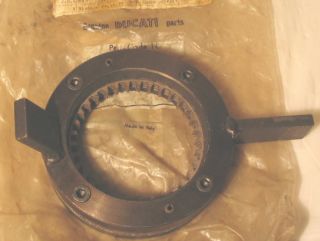

custom sized when ordering to ensure the correct fit.  Clutch

tool holder, made from a couple of old plates carefully aligned then

welded together. Some folk like a separate for the inner and outer

drum. This one works for me. The handle will wedge neatly onto a bolt

inserted in the upper engine mount bolt hole when you run

out of hands.

Clutch

tool holder, made from a couple of old plates carefully aligned then

welded together. Some folk like a separate for the inner and outer

drum. This one works for me. The handle will wedge neatly onto a bolt

inserted in the upper engine mount bolt hole when you run

out of hands. Counterhsaft

sprocket holder. Hose on end for preventing removal of

paint on swinging arm when wedged for either removal or replacement of

the SKF nut ( they're tight, very tight ! ). This is for a 16 tooth

sprocket. Can be purchased on the web.

Counterhsaft

sprocket holder. Hose on end for preventing removal of

paint on swinging arm when wedged for either removal or replacement of

the SKF nut ( they're tight, very tight ! ). This is for a 16 tooth

sprocket. Can be purchased on the web. Used with

1/2" drive breaker bar to remove the SKF countershaft sprocket nut. A

friend made this, past my skill level.

Used with

1/2" drive breaker bar to remove the SKF countershaft sprocket nut. A

friend made this, past my skill level. This

is the factory issued tool kit for the750 GT. Should be zinc plated

( it used to be ) and the screwdriver handle painted blue.

Unsure

about the 12 x 14 OE, it's marked Ducati. They came in a blue bag.There

could be a piece or two missing. Best left on a shelf

somewhere.

This

is the factory issued tool kit for the750 GT. Should be zinc plated

( it used to be ) and the screwdriver handle painted blue.

Unsure

about the 12 x 14 OE, it's marked Ducati. They came in a blue bag.There

could be a piece or two missing. Best left on a shelf

somewhere. Cheap 13mm

cut to tighten the lock nut on the clutch cable. Hard to access

otherwise, image close to acutal size.

Cheap 13mm

cut to tighten the lock nut on the clutch cable. Hard to access

otherwise, image close to acutal size. Cylinder

head nut tool, 16 x 17 mm for either size. 3/8" drive for torque

wrench. Use a torque wrench table to calculate settings.

Cylinder

head nut tool, 16 x 17 mm for either size. 3/8" drive for torque

wrench. Use a torque wrench table to calculate settings. Timing disc holder. A very handy timing disc, specifically for Ducati twins can be downloaded here.

Timing disc holder. A very handy timing disc, specifically for Ducati twins can be downloaded here.

Primary gear puller. There is a different factory tool for each variant in the primary gear size. The outer ring slides to provide a secure grip.

This blind bearing puller is used for the mainshaft brg. Warm the area around the bearing in the case before attempting removal.

This cam holder tool is required for holding the camshafts when removing the left hand threaded camshaft nut securing the bevel gear. Always use a new locking tab.

Factory supplied clutch holding tool, a good thing, usually better than the home mades ! The welded tabs secure the tool.

Factory countershaft sprocket nut removal tool.

The rocker pin extractor is essential for careful removal of the rocker pins when adjusting shims. You can make this at home.

The valve spring compressor is bulky. A smaller tool can be made to use in a drill press, but this one is factory supplied and works well.